A dynamometer force gauge is an essential tool for measuring force in a broad range of applications, from engineering to physical rehabilitation. As an integral part of quality control and product testing, understanding how to accurately use this device can make a significant difference in the validity of your results. Whether you are conducting tensile or compressive force tests, the dynamometer can provide you with precise readings that are critical in assessing the performance and safety of various materials and products. Below, you’ll find a comprehensive guide to help you master the use of a dynamometer force gauge.

Selecting the Right Dynamometer for Your Application

Choosing the right dynamometer force gauge starts with understanding your application needs. Key factors include the required force range, accuracy, resolution, and whether you need digital features like data storage. For industrial tasks, a high-capacity gauge may be essential, while laboratory work might call for a more sensitive device. The gd-200 3h, for example, offers precision and useful specs that suit many force measurement tasks.

Consider the environment and frequency of use. A gauge with a clear display and comfortable grip helps prevent fatigue during regular use, and models with proper durability are important if you’re working in dusty or damp conditions. Talking with trusted vendors or experts can help ensure you pick a reliable and long-lasting tool.

Understanding the Basics of a Dynamometer Force Gauge

Dynamometer force gauges measure force in newtons or pounds-force by converting physical force into a measurable reading on their display. Different types include mechanical and digital models, each with unique features for specific applications. Understanding static and dynamic force measurements is crucial, as static measurements occur when forces are applied slowly and no movement occurs, while dynamic measurements occur during motion.

Dynamometers operate by deforming a load cell or spring, which is translated into an electrical signal and numerical value. Familiarity with the specific model is essential, as exceeding the rated capacity can damage the device and compromise reading accuracy.

Step-by-Step Guide to Setting Up Your Dynamometer

To ensure accurate readings with a dynamometer, follow these steps: inspect the device for damage, assemble accessories securely, and calibrate according to the manufacturer’s standards. Understand the measurement units and align the dynamometer with the force being measured to avoid errors.

Conduct a test run with a known weight or force to verify the device’s functionality. If readings are off, recalibrate the device or troubleshoot according to the manufacturer’s instructions. Consistently reviewing the manual and familiarizing yourself with the manufacturer’s troubleshooting steps can help resolve setup issues quickly.

Best Practices for Accurate Force Measurement with Dynamometers

To ensure accurate force measurements with a dynamometer, follow best practices such as regularly checking calibration, using the dynamometer perpendicularly to the force being applied, and avoiding rapid or jerking motions. Maintaining a documented record of measurements is crucial for monitoring trends and identifying discrepancies.

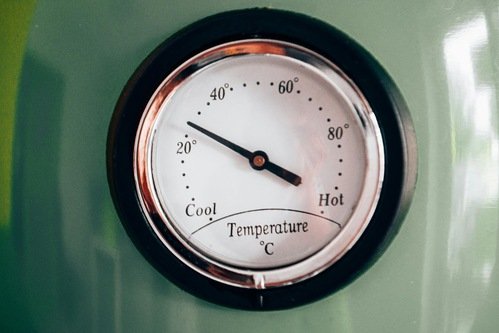

Environmental factors like temperature, humidity, and vibration can also impact readings, so adjust for them according to manufacturer guidelines. Measurements should be taken in a controlled environment or at a consistent time of day to minimize external variables. This helps maintain the gauge’s precision over time.

Maintaining and Calibrating Your Dynamometer Force Gauge

Proper maintenance and calibration are crucial for the longevity and accuracy of a dynamometer. Store the device in a clean, dry place, avoid extreme temperatures or chemicals, and regularly inspect the gauge for signs of wear or damage. Regular calibration should be a routine part of your maintenance schedule, with frequency depending on usage and precision.

Consult specialized calibration services for calibration needs and keep a log of calibration dates and results. Refer to the manufacturer’s manual for detailed maintenance recommendations, as following these guidelines can help avoid common pitfalls and maintain reliability.

Overall, a dynamometer force gauge is a powerful tool when used correctly. By carefully selecting the right model, ensuring proper setup, adopting best practices, and committing to regular maintenance and calibration, you can rely on your dynamometer to provide accurate force measurements for a wide array of applications. The insights gained from using this instrument can inform decisions and improve the overall quality of your work, solidifying its place as a staple tool in many industries.